These locking tubes are available in a variety of lengths and in both cast acrylic plastic and 6061-T6 aluminum. These tubes are a substantial upgrade over the first generation of watertight enclosure tubes.

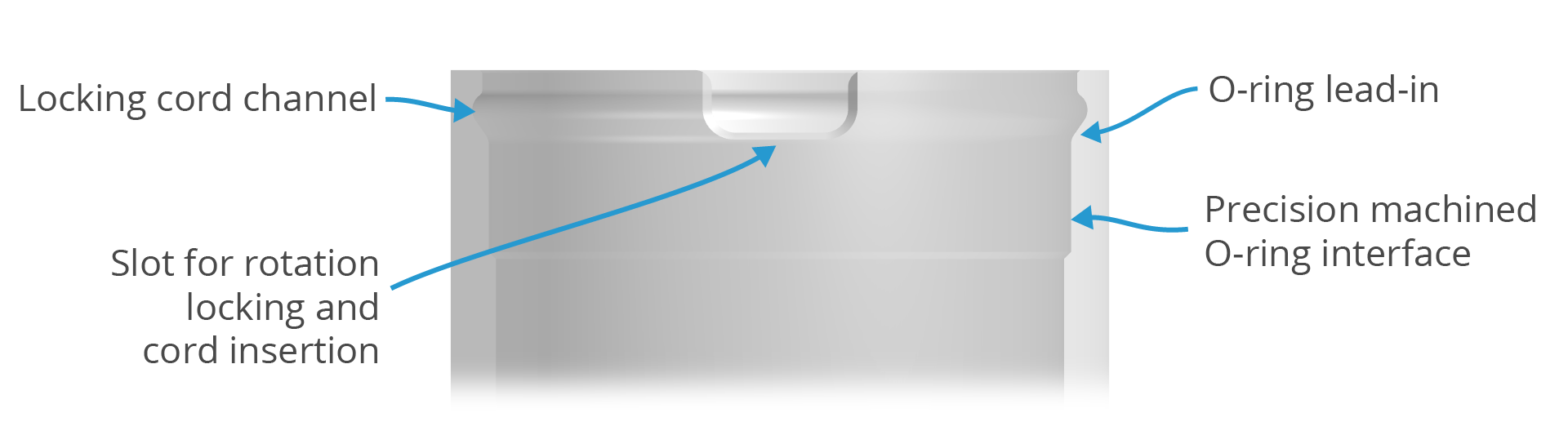

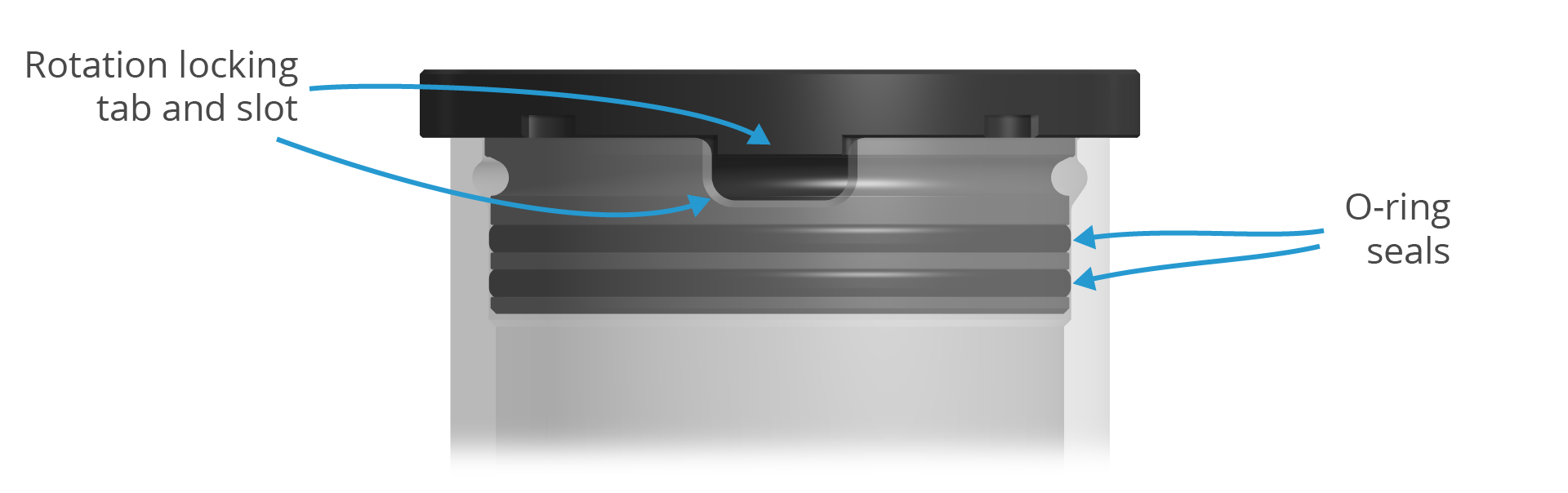

Both the acrylic and aluminum tube options have precision machined O-ring interfaces at each end, ensuring a consistent and reliable fit with the sealing flange. A smooth surface finish ensures proper sealing between the O-ring flange and the tube. Also machined into the ends is a gland for a locking cord and a slot for cord insertion. You can read more about the locking feature and see a diagram of how it works on the main watertight enclosure product page.

The slot for cord insertion doubles as an anti-rotation feature, mating with a feature on the flange. This keeps the flange in a consistent orientation with the tube and prevents the user from rotating the flange and damaging anything inside the enclosure.

Because of the precision machined interface, the tubes are no longer available in custom lengths

Specifications

| Parameter | Value |

|---|---|

| Material | Cast Acrylic or 6061-T6 Aluminum |

| Depth Rating | Varies on Length and Material; Depth Rating in Product Selection Dropdown |

2D Drawings

WTE2

WTE2-LOCKING Tubes (.pdf)

3D Models

WTE2

WTE2-M-LOCKING-TUBE-100-R1 (.zip)

WTE2-M-LOCKING-TUBE-150-R1 (.zip)

WTE2-M-LOCKING-TUBE-300-R1 (.zip)

WTE2-P-LOCKING-TUBE-100-R1 (.zip)

WTE2-P-LOCKING-TUBE-150-R1 (.zip)

WTE2-P-LOCKING-TUBE-300-R1 (.zip)